Product Introduction

Material: 1mm aluminum sheet is used as the raw material. Aluminum sheet features lightweight, moderate strength, and excellent corrosion resistance, making it suitable for a variety of applications where weight and corrosion resistance are critical.

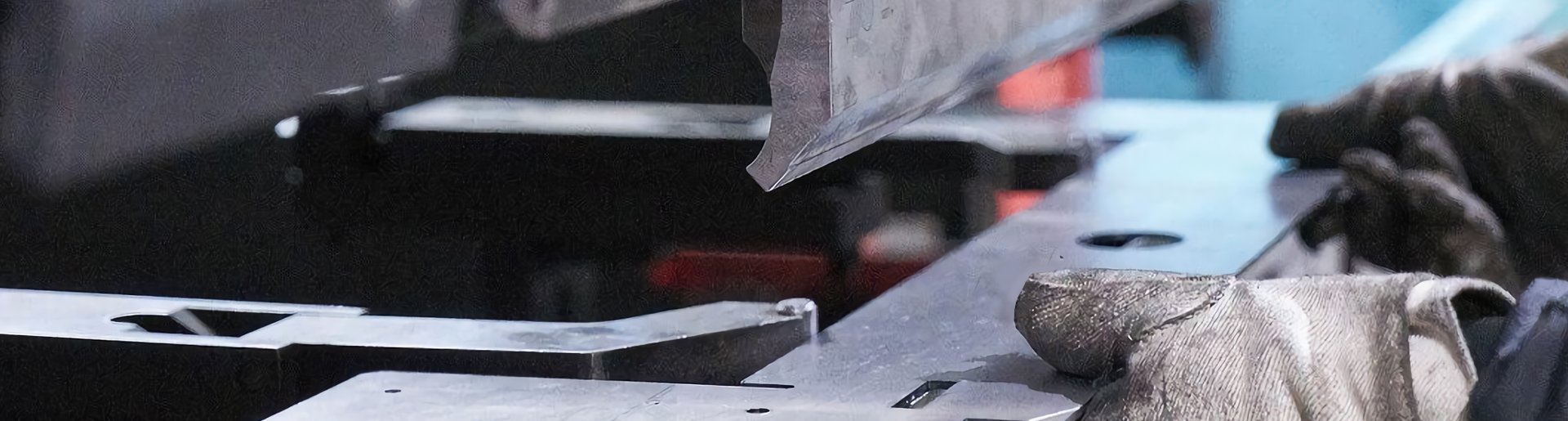

Processing: Laser cutting is used to precisely cut the desired shape, resulting in a smooth, burr-free cut. Bending is then performed to create a specific three-dimensional structure to meet diverse installation and usage requirements.

Surface Treatment: Brushed and anodized finishes are available. Brushed finish imparts a unique texture; anodizing forms a dense oxide film on the aluminum sheet surface, further enhancing its corrosion resistance and aesthetics.

Product Advantages

Lightweight and Durable: 1mm aluminum sheet is lightweight, easy to install and transport, and offers excellent corrosion resistance, making it suitable for a variety of complex environments and providing a long service life.

High Precision: Laser cutting and bending processes achieve precision machining with a tolerance of ±0.05mm, meeting the needs of various applications requiring precise installation and ensuring a perfect fit with other components. Aesthetic Diversity: Surface brushing and anodizing not only enhance the product's corrosion resistance but also provide a variety of aesthetic options to meet diverse customer needs.

Why Choose Us?

Equipment Advantages: We own our own laser cutting and bending machines, enabling flexible production scheduling, effectively controlling production costs, quickly responding to customer needs, and ensuring timely delivery.

Precision Guarantee: Our professional technical team and advanced processing equipment enable us to maintain precise tolerances of ±0.05mm, providing customers with high-precision products and reducing installation and commissioning issues.

Quality Certification: As an ISO-certified manufacturer, we adhere to a strict quality management system, rigorously controlling every step from raw material procurement, production, and processing to finished product inspection to ensure consistent and reliable product quality.

Customization Services: In addition to standard products, we offer customized services tailored to individual customer needs, including size, shape, and surface treatment, to fully meet your individual needs.