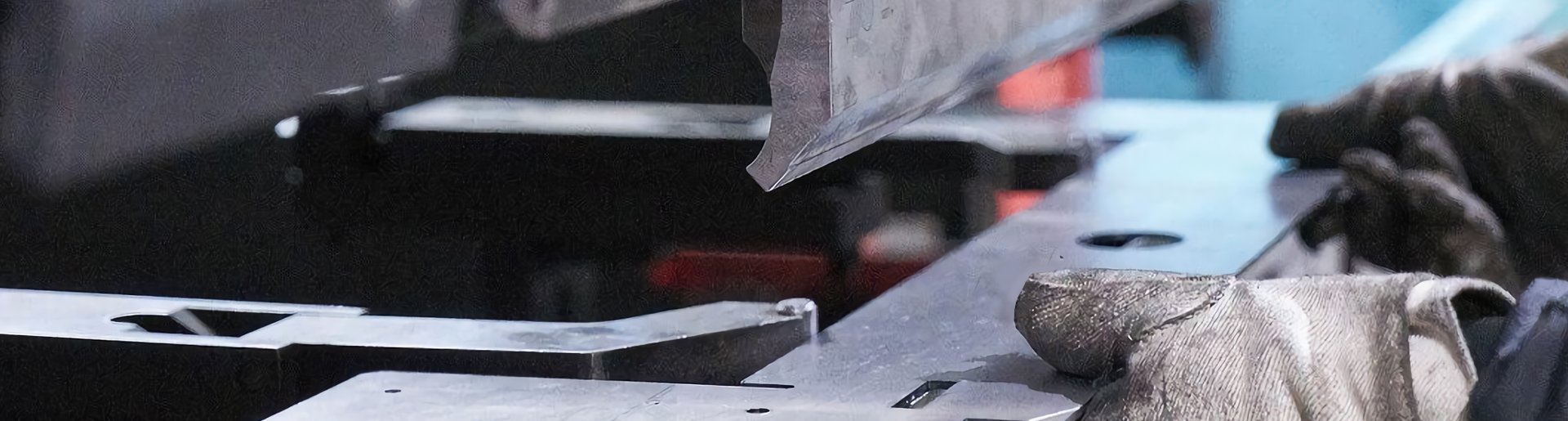

carbon steel pipe bending accessories | Pipe clamp tolerance ±0.3~0.5mm

The production of carbon steel pipe bending is a precision process that integrates material science, machining and heat treatment technology. The core of this process is to maintain the corrosion resistance, strength and structural integrity of the carbon steel pipe after bending. The following is a detailed analysis of the key manufacturing processes and technical points of the cold bending process:

Material type: Carbon steel (such as Q235B,Q345) is widely used due to its excellent ductility and corrosion resistance.

Pretreatment: The pipe surface must be cleaned (remove oil and oxide layer) and the dimensions must be checked to ensure that there are no defects.

Different processes are selected according to the pipe diameter, wall thickness and bending radius:

Cold bending process (room temperature bending)

Applicable scenarios: thin-walled pipes (wall thickness <10% of the pipe diameter), small angle bending.

Process category:

Rolling: Use three or more rolling dies to gradually form, suitable for large radius bending.

Pressing: Use hydraulic press compression molding, high precision, but may produce elliptical deformation.

Rotational bending: The tube is rotated while being pushed by the fixed die, suitable for complex spatial curves.

Stress relief: Anneal the cold-bent parts to reduce residual stress.

Surface treatment: Pickling passivation (nitric acid + hydrofluoric acid solution) to restore corrosion resistance, or electrolytic polishing to improve surface quality.

Shaping and calibration: Hydraulic rounding machine corrects ovality, laser detection ensures tolerance (usually ± 0.5 mm).

Quality control

Non-destructive testing: Ultrasonic detection of internal defects.

Mechanical property testing: Sampling verification flattening and expansion tests.

Our high-quality carbon steel pipe clamps are the ideal solution for safe and durable pipe fixing. Made with carbon steel pipe cold bending technology, this product provides excellent quality and reliability for a variety of applications. To ensure perfect fit and stability, the design accuracy is ± 0.3–0.5 mm.

Why choose our pipe clamps?

With many years of experience in carbon steel and steel pipe bending, we provide you with products that combine precision, durability and aesthetics. Our pipe bending components are manufactured to the highest standards and will reliably support your projects.