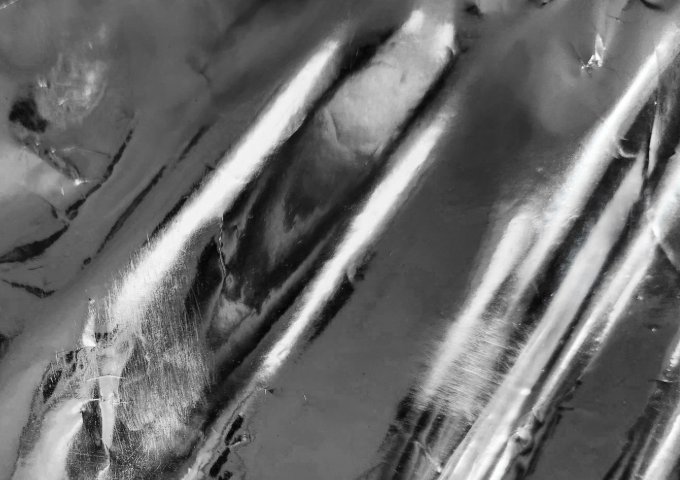

Causes and Solutions for Wrinkling During Metal Stretching

The metal stretching process is widely used in a variety of fields, including automotive parts, electronic components, and hardware, and is a core process in the production of custom metal parts. However, in actual production, wrinkling during the stretching process plagues many factories. This problem not only compromises the parts' cosmetic precision and structural integrity, but can also lead to batch scrapping, significantly increasing production costs and time pressures. As a small custom metal parts manufacturer established in 1997 and dedicated to stamping and stretching for over two decades, we have accumulated extensive experience in addressing metal stretching wrinkling. We have compiled and shared key technical points to help our peers and customers efficiently address this production challenge.

Metal Materials Prone to Wrinkling During Stretching

Due to their inherent properties, different metal materials exhibit significantly different wrinkling propensities during stretching. The following materials require special attention:

Low yield strength, high elongation materials: such as pure aluminum (1050 and 1100 series) and pure copper (T2 and T3 grades). These materials exhibit good plasticity but weak deformation resistance, making them prone to wrinkling during stretching due to uneven localized stress.

Thin-gauge sheet metal: Cold-rolled steel and stainless steel sheets less than 1mm in thickness are prone to edge shrinkage and wrinkling during the die closing and forming process due to their inherent lack of rigidity.

High-hardness heat-treated materials: such as quenched 45# steel and 65Mn steel. While strong, they exhibit poor plasticity, resulting in poor material flow during stretching and prone to wrinkling around rounded corners.

Core Causes of Metal Wrinkling During Stretching

Based on actual production cases, metal wrinkling during stretching is primarily caused by the following four factors:

Unbalanced Material Flow: During the stretching process, if the gap between the punch and die is unreasonable or the blank holder force is too weak, the metal material, under the action of radial stretching and tangential compression, will flow too rapidly in certain areas. Excess material cannot be dispersed in time, ultimately forming wrinkles.

Mold Design Flaws: A too small die corner radius increases material flow resistance, leading to localized material accumulation. Concentricity deviation between the punch and die causes asymmetrical force on the material, causing unilateral wrinkling. Furthermore, insufficient mold surface finish and excessive friction can hinder uniform material flow.

Improper Process Parameter Settings: Excessive stretching speed prevents the material from fully deforming, leading to localized stress concentration. Improper blank holder force adjustment: Too low a stretching speed will not suppress wrinkling, while too high a stretching force may cause cracking. Furthermore, incorrect selection of stretching times, where the deformation exceeds the material's limit, can also cause wrinkling. Material Pretreatment Issues: Unrelieved internal stresses generated during the rolling process, or the presence of oil and impurities on the metal sheet surface, can affect uniform stress distribution and flow, increasing the risk of wrinkling.

Prevention and Solutions for Metal Wrinkling During Stretching

To address the aforementioned causes, we have developed a set of practical prevention and solutions to effectively reduce the probability of wrinkling:

(I) Preventive Measures

Optimize Material Selection and Pretreatment: Based on product requirements, prioritize materials with moderate yield strength and standard elongation. Anneal the sheet to eliminate internal stresses. Thoroughly clean the surface of the material from oil and impurities before stretching to ensure cleanliness.

Improve Die Design: Rationally design the die corner radius, generally 5-8 times the material thickness, to reduce material flow resistance. Ensure the coaxiality error between the punch and die is less than 0.02mm to ensure symmetrical stress distribution. Improve the die surface finish to below Ra0.8μm to reduce friction. Precisely set process parameters: Adjust the drawing speed based on material properties and product shape, generally maintaining a range of 50-150mm/s. Determine the optimal blank holder force through die trials, ensuring the material does not wrinkle or crack. For products with significant deformation, perform multiple stretches, keeping the deformation within the material's tolerances for each stretch.

(II) Solutions for Wrinkling

Treatment of Minor Wrinkles: If only minor edge wrinkles occur, increase the blank holder force appropriately, reduce the drawing speed, and continue stretching. After stretching, manually polish or polish to remove minor surface wrinkles and ensure product accuracy.

Treatment of Moderate Wrinkles: If wrinkles are significant, stop stretching, check the die clearance and coaxiality, and adjust them to an acceptable range. Replace the blank holder, increase the blank holder area, and retest the die. If material accumulation is severe, perform a partial trimming of the wrinkled area before re-stretching.

Severe Wrinkling Treatment: If a product exhibits severe wrinkling that cannot be repaired, the product must be scrapped and the cause of the wrinkling re-analyzed. Mold defects can be repaired, process parameters adjusted, and, if necessary, materials replaced to prevent recurrence.

Over the years, Kailai Machinery, leveraging its in-depth research and practical experience in metal drawing processes, has successfully resolved wrinkling issues for numerous customers, ensuring product quality and production efficiency. In the future, we will continue to share our industry experience and contribute to the high-quality development of the metalworking industry.