Product Basic Information

Material: Made of 0.5mm SPCC, which offers excellent formability and ensures the gasket's shape stability, providing a solid seal.

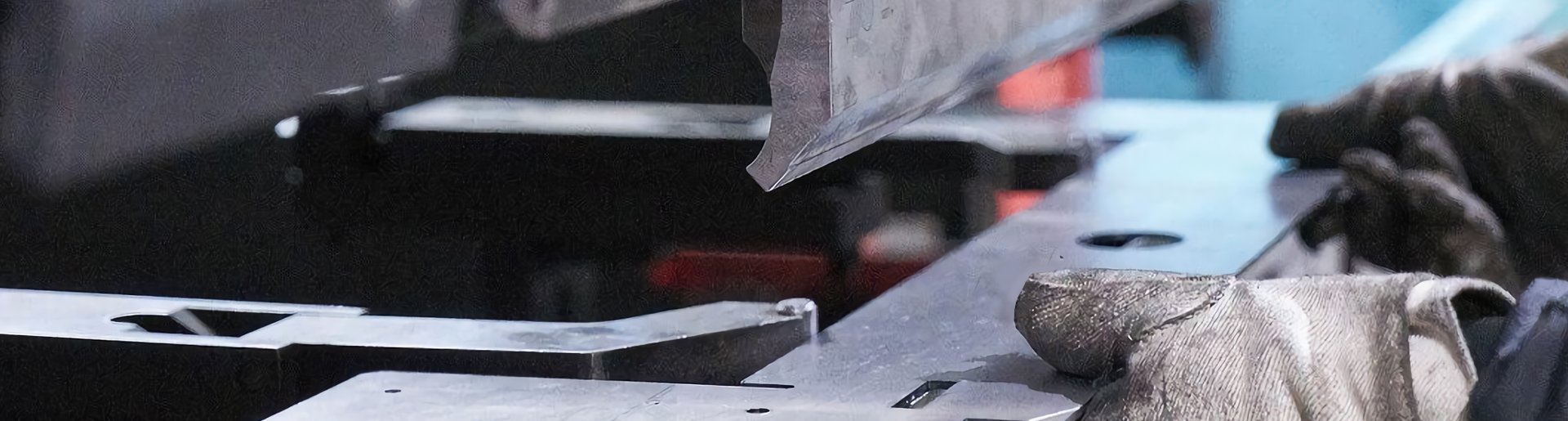

Processing: Precision stamping ensures dimensional accuracy and precise fit with other components for optimal performance.

Surface Treatment: Galvanized surface treatment not only enhances the gasket's rust and corrosion resistance, extending its lifespan, but also enhances its appearance and quality, ensuring it remains in excellent condition in various environments.

Applications

Automotive: Suitable for use in automotive engine exhaust systems, sealing between the exhaust manifold and exhaust pipe, preventing high-temperature exhaust gas leakage and improving exhaust system efficiency and stability. It also protects against vibrations during driving and maintains a strong seal. It can also be used in the pipe connections of automotive brake systems to prevent brake fluid leakage and ensure safe and reliable operation.

Mechanical Equipment: In compressors, pumps, and other mechanical equipment, these seals are used to seal between components, preventing internal gas or liquid leakage, maintaining normal operating pressure, and ensuring stable operation. They are also used in cooling system piping connections for various types of machinery, preventing coolant leaks and ensuring effective heat dissipation.

Industrial Piping: In industrial piping systems in the petroleum, chemical, and power industries, these seals serve as sealing components at flange joints, adapting to the transportation needs of various media (such as oil, natural gas, and steam), effectively preventing media leakage and avoiding environmental pollution and production safety hazards.

Why Choose Us

Reliable Quality: We rigorously control our production processes. From the selection and procurement of SPCC materials to stamping, forming, and galvanizing, each step is inspected by professional quality inspectors to ensure high product quality standards. Extensive testing simulates actual application environments to verify our products' excellent sealing and corrosion resistance.

Flexible Customization: We offer customized services based on customer requirements for size, shape, mounting hole locations, and other features to meet diverse application scenarios and installation requirements. We can also provide optimized surface treatment and material selection solutions for specific application environments and media.

High-quality service: We have a professional pre-sales technical support team that can quickly respond to customer inquiries and provide customers with professional product selection suggestions; the after-sales team promptly handles customer feedback issues and provides comprehensive after-sales services such as repairs and replacements, so that customers have no worries.