Product Overview

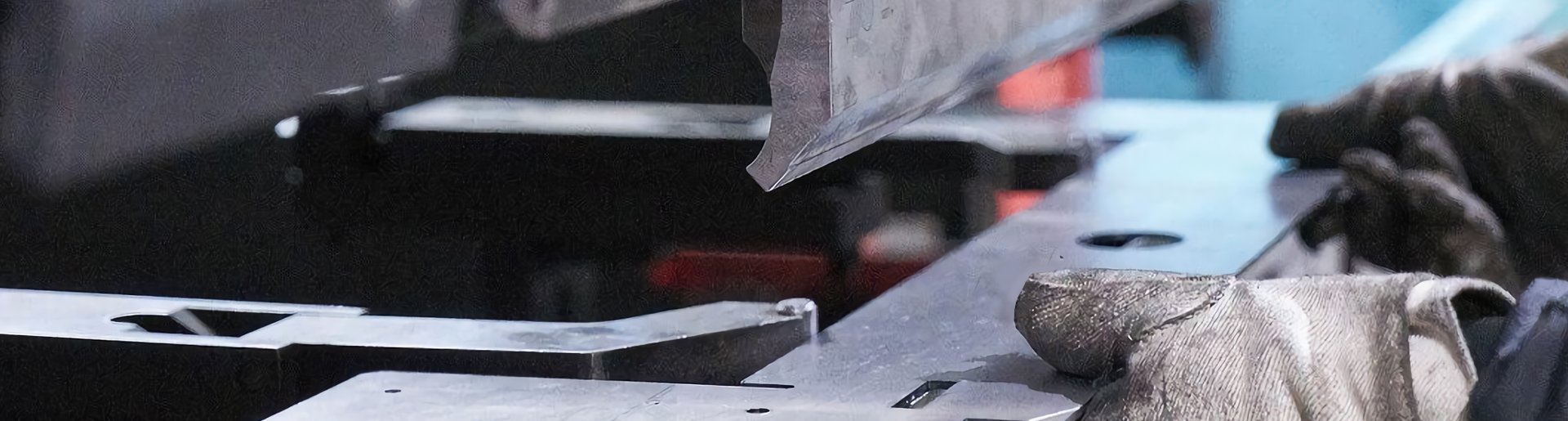

This embedded component is welded from HRB400 rebar and 10mm thick Q235B carbon steel plate. Through a special treatment process, the welded joint strength exceeds the limitations of the original material, providing higher load-bearing capacity. The surface is hot-dip galvanized to effectively isolate air and moisture, significantly improving corrosion resistance and extending service life in harsh outdoor environments.

Core Advantages

Mechanical Properties

The inherent high strength of HRB400 rebar, combined with the stable base of Q235B steel plate, and welded reinforcement, provides excellent overall tensile and shear resistance, capable of withstanding long-term loads, vibrations, and shocks in building structures, ensuring a secure connection.

Corrosion Resistance

The dense and uniform hot-dip galvanizing layer provides dual "physical and chemical" protection for the embedded component: it physically blocks moisture and salt attack, and chemically forms a passivation film to slow rust, making it suitable for high-corrosion-risk environments such as humid and coastal areas.

Process Assurance

Welding procedures strictly adhere to specifications, from pre-weld rust removal and cleaning to precise control of welding parameters (matching current, voltage, and welding speed), and post-weld flaw detection to ensure reliable joint quality. The hot-dip galvanizing process controls the thickness and adhesion of the zinc layer, ensuring both corrosion resistance and aesthetics.

Application Areas

Curtain Wall Engineering

Serving as the connecting link between the curtain wall keel and the main structure, it withstands the weight and wind loads of glass and stone curtain walls, ensuring the stability of the curtain wall system. It is suitable for the exterior decoration of large buildings such as commercial complexes and high-end office buildings.

Bridge Steel Structures

Used for pre-embedded bridge bearings and guardrail base connections, its high strength and corrosion resistance ensure the safety of bridge structures under the alternating effects of traffic loads and the natural environment. It is suitable for infrastructure projects such as highway and railway bridges.

Rail Transit Facilities

In subway and light rail projects, it is pre-embedded in platform and tunnel structures to provide anchor points for equipment supports (such as lighting and ventilation) and contact network foundations, tackling the humid and frequently vibrating underground environment. (IV) Industrial Plant Construction

Pre-embedded steel columns and crane beams are embedded in the plant's foundation to support equipment installation and lifting loads, making them suitable for industrial applications such as heavy chemical and machinery manufacturing, which require high structural strength.

Customized Services

Drawing Customization

We support customers by providing design drawings and 3D models, accurately reproducing their customized requirements. From rebar bending angles and steel plate hole locations to overall dimensional tolerances, we collaborate throughout the entire process to ensure the product is tailored to the project's unique installation logic.

Material Customization

We cover diverse material requirements:

Higher strength grades such as HRB500 are available for rebar, suitable for ultra-high-rise and heavy-load projects;

Low-alloy materials such as Q355B are available for steel plates, enhancing structural toughness;

Stainless steel and weathering steel materials can be customized for special scenarios to meet extreme corrosion and weathering requirements.

Surface Treatment Customization

Hot-dip galvanizing is standard, and the zinc layer thickness can be adjusted as needed to meet protection requirements in highly corrosive environments. (IV) Thickness and Size Customization

Steel plate thicknesses range from 5mm to 50mm, adapting to different load levels. Flexible adjustments to rebar diameters and bending patterns meet the full range of "lightweight anchoring - heavy-load support" requirements. Custom production is available for everything from micro-architectural embedded components to large infrastructure components.

Whether you're working on a construction project, bridge infrastructure, or industrial facility, we offer professional craftsmanship and customized services to provide high-performance, long-life embedded solutions, helping you reduce costs, increase efficiency, and enhance quality.