How to choose the number of cavities in metal stamping die production?

Choosing the number of cavities (i.e., "number of cavities") is a key decision in metal stamping production, balancing production efficiency, cost control, and product quality. This decision requires a comprehensive assessment based on multiple factors, including the characteristics of the metal stamping part, production requirements, and stamping equipment conditions.

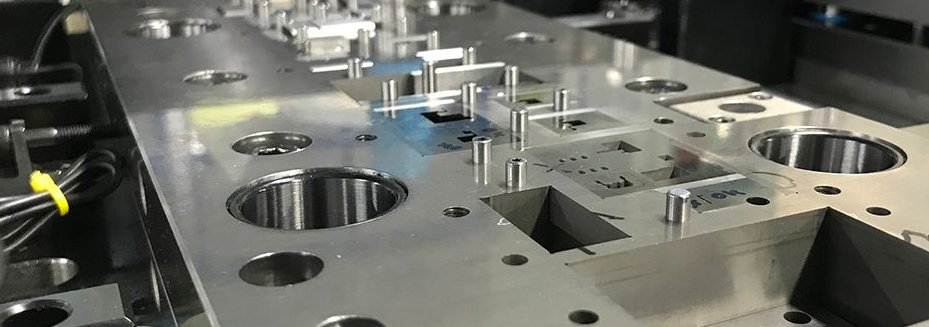

As an experienced manufacturer of custom metal parts, Kailai Machinery has extensive experience in developing its own dies. We would like to share our selection logic and key influencing factors with our partners to help manufacturers of small and medium-sized custom metal parts systematically derive the optimal number of cavities:

Core Principle: First, Clarify "Production Goals" and "Constraints."

Before selecting the number of cavities, you must answer two fundamental questions to avoid blindly pursuing multiple or single cavities.

Production Requirements: How many metal stamping parts will be produced, and how quickly?

This refers to annual output/monthly output and lead time. For rapid mass production (e.g., standard metal gaskets or small connectors), multi-cavity production is preferred. For small-batch customization (e.g., precision hardware accessories or custom-shaped stamped parts), single or fewer cavities offer greater flexibility and reduce mold idleness.

Constraints: Can existing metal stamping resources support this?

These factors include press tonnage, nominal pressure, slide stroke, worktable size, workshop die storage space, and feed mechanism compatibility. These factors directly determine the upper limit on the number of cavities (e.g., a small desktop press cannot accommodate multi-cavity dies).

Key Influencing Factors: Eight Dimensions Determine the Upper Limit and Rationality of the Number of Stamping Cavities

1. Annual Production and Production Cycle of Metal Stamping Parts (Core Driving Factor)

The number of cavities is essentially a measure of "stamping output per unit time" and must be quantified using the following formula:

Required Number of Cavities ≈ (Annual Total Production ÷ Annual Effective Production Time ÷ Single-Die Stamping Cycle) ÷ Yield

Formula Explanation: The single-die stamping cycle encompasses the entire process of "feeding → stamping → part removal" (typically 3-10 seconds per die for small, simple parts, 15-30 seconds per die for complex parts). Yield is determined by the stability of the stamping process (conventional metal stamping yields are 85%-98%, while precision parts require ≥95%).

Rules: For custom metal parts with annual production volumes below 100 pieces, a single or two-cavity solution is sufficient; for 100k-500k pieces, a two- to four-cavity solution is recommended. For parts exceeding 500k pieces (such as standard fasteners), a multi-cavity solution with 4- to 8-cavities can be considered.

2. Metal Stamping Part Size and Complexity (Quality Constraints)

The more cavities there are, the higher the stamping die machining precision requirements and the more difficult it is to control the consistency of the metal part. A trade-off must be made based on part characteristics:

| Metal Stamping Part Characteristics | Recommended Cavity Number | Cause Analysis |

| Small, simple parts (e.g., metal gaskets, flat washers) | Multiple cavities (4-8 cavities) | Small size (diameter <50mm), no complex forming (e.g., no bending/punching), easy die edge alignment, and easy stamping consistency |

| Medium-sized, precision parts (e.g., electronic connector springs) | Medium-small cavities (2-4 cavities) | Dimensional tolerances must be controlled (e.g., thickness ±0.02mm, hole position deviation ≤0.03mm). Multiple cavities are prone to accuracy fluctuations due to feed deviation and edge wear |

| Complex formed parts (e.g., bent hardware, multi-punched parts) | Single-cavity (rarely 2-cavity) | Parts containing multiple stamping steps (e.g., bending + punching + Trimming), multi-cavity molds are prone to process synchronization issues, leading to part deformation and cracking. |

| Thin-walled metal parts (thickness < 0.5mm) | Fewer cavities (1-2 cavities) | Uneven pressure during stamping can easily lead to wrinkles and springback. Fewer cavities facilitate precise control of stamping speed and pressure, reducing scrap. |

3. Press Parameters (Hardware Limit)

The number of cavities must not exceed the press's "load capacity." Three key parameters must be considered:

Nominal Pressure (Tonnage): The greater the number of cavities, the greater the total force applied during a single stamping (total force = single-cavity punching force × number of cavities + feed resistance). The requirement is "total force ≤ press nominal pressure × 80%" (allow a 20% safety margin to prevent equipment overload).

Worktable Dimensions: The length and width of the stamping die must be ≤ the effective dimensions of the press worktable (typically leaving 50-100mm of operating clearance). Multi-cavity molds are larger, so confirm whether the worktable can accommodate them.

Slide Stroke and Closure Height: The mold's closing height (the distance from the bottom dead center of the slide to the work surface during stamping) must be between the press's "minimum closing height" and "maximum closing height." Multi-cavity molds may have more cutting edge layers, so the closing height compatibility must be verified.

4. Cost Balance (Economic Rationality)

The greater the number of cavities, the inverse relationship between the "upfront mold investment cost" and the "later stamping cost per piece." The "payback period" must be calculated to determine cost-effectiveness.

Cost Characteristics of Multi-cavity Stamping Dies:

Advantages: Low cost per piece (spreading out equipment depreciation, labor, and feed costs; for example, a four-cavity die can cost over 50% less per piece than a single-cavity die) and high production efficiency.

Disadvantages: High mold cost (doubling the number of cavities results in a mold cost of approximately 14-18 times as much. For example, a single-cavity metal stamping die costs 15 yuan, while a four-cavity die may cost 40k-50k yuan). Long development cycle (multi-cavity dies require more precise edge alignment and feed path design).

Cost Characteristics of Low-Cavity Stamping Dies:

Advantages: Low mold cost (single-cavity is over 60% cheaper than four-cavity), fast debugging (problems are easy to locate, such as deformation of a single-cavity stamping part, requiring only adjustment of a single set of cutting edges), and flexibility (ability to quickly switch between different parts).

Disadvantages: High unit cost (low efficiency, high labor/equipment cost distribution), and low production capacity (difficulty meeting large-volume orders).

Decision Logic: If the metal stamping part has a long lifecycle (>1.5 years) and stable production volume, the high upfront investment of a multi-cavity mold can be quickly recouped through low unit cost. For short-term custom orders (<6 months) and small batches (<50k pieces), a low-cavity mold is more cost-effective (avoiding production halts before mold costs are recovered).

5. Difficulty in Stamping Die Processing and Commissioning (Feasibility)

The difficulty of manufacturing and maintaining metal stamping dies increases exponentially with the number of cavities:

Processing Accuracy: Multi-cavity dies must ensure consistent cutting edge dimensions across cavities (e.g., a blanking clearance of ±0.01mm). High-precision wire cutting and grinding are required. Otherwise, "same die, different parts" (e.g., excessive burrs on some parts) can easily occur.

Feeding Balance: Multi-cavities require a multi-station feeding mechanism to ensure that the metal sheet enters each cavity simultaneously. Otherwise, "missed punches" and "offset" can occur, and the commissioning cycle may be extended from three days to one week.

Maintenance Cost: If a cavity edge in a multi-cavity die is worn (e.g., a blunt punch), the entire die must be disassembled and replaced, resulting in significant downtime (typically 4-8 hours). In contrast, repairs on single-cavity dies only take one to two hours and do not affect production of other orders.

6. Metal Material Properties (Process Compatibility)

Different metal materials have different stamping properties (hardness, ductility, and springback) and therefore differ in their tolerance for the number of cavities:

High-ductility materials (such as pure copper, pure aluminum, and mild steel): They are less susceptible to cracking during stamping and are suitable for multiple cavities (4-8 cavities), providing good forming consistency and minimal edge wear.

Medium-hardness materials (such as brass and Q235 steel): Stamping pressure must be controlled. A medium-to-small number of cavities (2-4 cavities) is recommended to avoid premature mold damage due to concentrated pressure.

High-hardness/brittle materials (such as 304 stainless steel and spring steel): They are prone to cracking and springback during stamping. A single or two-cavity die is recommended, and pre-annealing and die coating (such as nitriding) are recommended to reduce scrap.

7. Quality Inspection Efficiency (Hidden Costs)

The greater the number of cavities, the greater the workload and difficulty of quality inspection for metal stamping parts:

Single-cavity/2-cavity: 100% inspection is possible (e.g., dimensional measurement, burr inspection, and forming accuracy), with high inspection efficiency (only 1-2 parts per die need to be inspected), making it easy to promptly detect problems such as mold edge wear and feed deviation.

4-cavity/8-cavity: Full inspection is time-consuming (e.g., 8 parts per die with 8 cavities need to be inspected), and sampling inspection is typically limited (e.g., 15% sampling). This may miss defective parts (e.g., burrs caused by excessive blanking clearance in individual cavities), increasing subsequent customer returns and rework costs.

For "high-demand metal parts" (e.g., automotive safety components and medical equipment accessories), strict full inspection is required. Even with high production volumes, it is recommended to limit the number of cavities (2-4 cavities) to avoid quality risks.

8. Future Capacity Flexibility (Long-Term Planning)

If you plan to expand production or switch metal stamping product categories in the future, you need to allow for flexibility:

If you anticipate doubling your production volume in 6-12 months, you can choose a "modular multi-cavity mold" (e.g., initially install a 2-cavity mold, which can be increased to 4 cavities later by simply adding cavity modules) to avoid re-opening the mold.

If you plan to produce similar metal parts with different specifications in the future (e.g., gaskets of varying sizes, connectors with different hole locations), we recommend choosing a "single-cavity/2-cavity universal mold" (which only requires replacing the cavity insert and punch). This offers greater flexibility and a mold reuse rate of over 70%.

Summary of the Metal Stamping Cavity Count Decision Process

Define Requirements: Calculate the annual production volume and delivery cycle for metal stamping parts to determine the minimum production capacity requirement;

Hardware Verification: Determine the maximum number of cavities based on the press's nominal pressure, table size, and closing height;

Product Evaluation: Narrow the feasible range of cavities based on the metal part's size, complexity, and material properties;

Cost Calculation: Compare mold costs, unit costs, and payback periods for different cavitation counts to select the economically optimal solution;

Feasibility Verification: Confirm mold processing difficulty, inspection efficiency, and future production capacity flexibility to ultimately determine the number of cavities.

Through these steps, you can avoid the problems of blindly adding more cavities, resulting in idle molds and cost waste, or insufficient single-cavity production capacity and missed orders. This allows you to precisely match the number of cavities in metal stamping molds to production needs, improving the production efficiency and market competitiveness of small and medium-sized custom metal parts manufacturers.

As an experienced custom metal parts manufacturer, Kailai Machinery has the ability to develop its own molds, offering fast turnaround times, reasonable prices, and high quality. If you require one-on-one customization, we can provide you with tailored services.