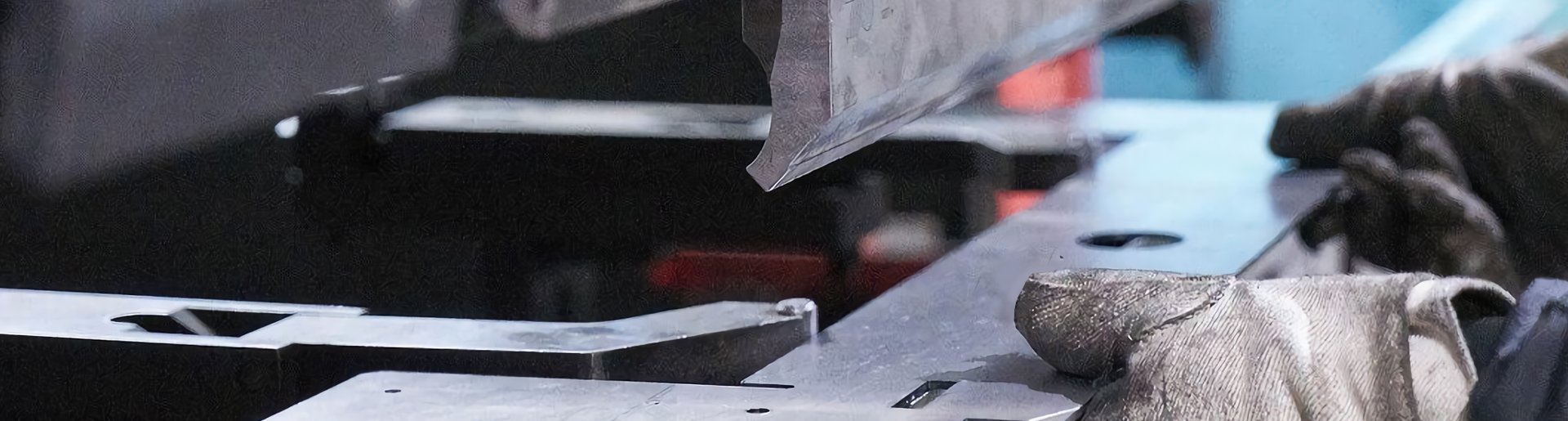

Part Details

Material: Made of high-quality steel, hot-dip galvanized for enhanced corrosion resistance, it withstands long-term rust-proofing in harsh environments such as humidity, acidity, and alkalinity.

Thickness: Ranges from 8-10mm, offering excellent structural strength and stability, capable of withstanding significant external forces and loads.

Surface Treatment: The hot-dip galvanizing process creates a dense zinc coating on the steel surface, significantly enhancing rust resistance and increasing surface hardness, reducing wear and tear during daily use. The hot-dip galvanizing treatment also provides a more aesthetically pleasing appearance.

Structural Design: Long, rectangular holes facilitate fine-tuning during installation, meeting the precise installation requirements of various scenarios and facilitating bolt connection to other components.

Applications

Construction: Can be cast as an embedded component in concrete, used to connect steel and concrete structures. For example, in high-rise steel buildings, it connects steel beams and columns to concrete foundations to ensure overall structural stability. In industrial plant construction, it is used to secure heavy components such as crane beams. They can also be used in curtain wall installation, connecting the curtain wall keel to the main structure, ensuring the curtain wall's safety and stability.

Industrial Equipment Installation: When installing large machinery and equipment, such as machine tools and heavy motors, these components serve as connectors for the equipment base, firmly connecting the equipment to the ground foundation. The long, rectangular holes facilitate alignment and fine-tuning of the equipment during installation, ensuring precise installation.

Bridge Engineering: In bridge construction, these components are used to connect ancillary structures, such as guardrails and lighting, to the main structure, enhancing the stability of these structures and improving the safety of the bridge.

Introduction to Industrial Embedded Parts

Definition: Industrial embedded parts are pre-installed (buried) components within concealed construction. They are embedded in their designated locations during the pouring of the structure and used for overlap during the construction of the superstructure, facilitating the installation and securing of external equipment foundations.

Functions: First, they provide reliable connections, firmly connecting external equipment and components to the main structure, allowing them to function as a single unit and share loads. For example, connecting steel structures to concrete structures. Second, they facilitate installation. When installing equipment or other components, direct connections can be made through embedded components, eliminating the need for extensive drilling and other disruptive operations in the main structure. This improves construction efficiency while ensuring installation accuracy.

Common types include steel plate embedded components (such as this product) for flat connections; bolt embedded components for securing equipment subject to high tension and torque; and pipe embedded components for later wiring and conduit installation.