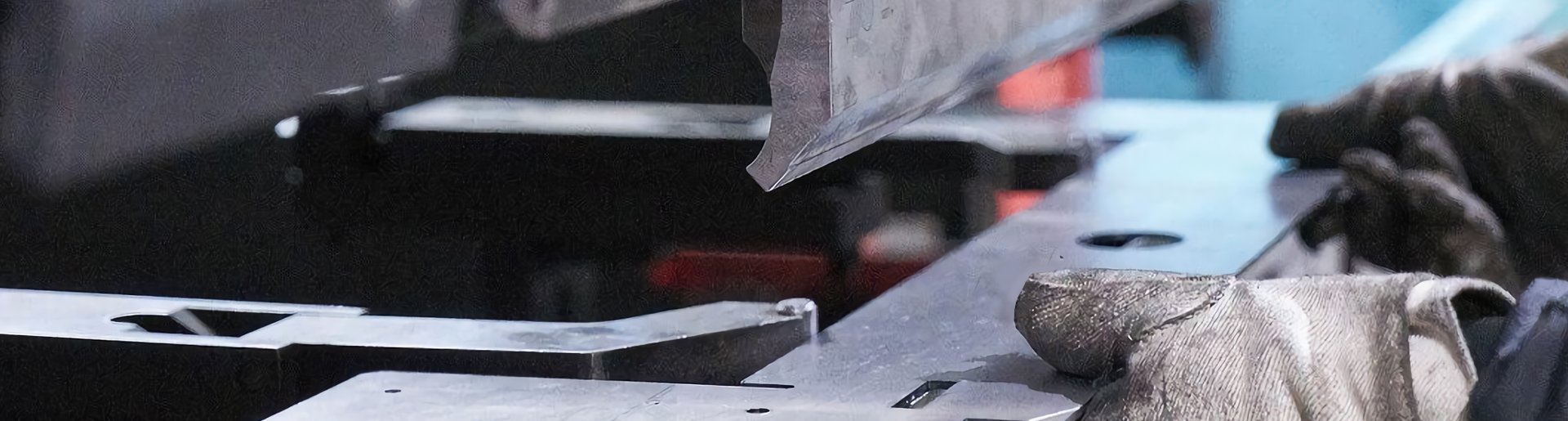

High-quality pipe bends – precision stainless steel pipe bends for the highest demands

Stainless steel siphon elbows are manufactured using advanced pipe bending technology, with an elegant appearance and powerful functionality.

Our stainless steel pipe bend fittings are made from precision bent 10 mm diameter 304/316 stainless steel pipes. They are corrosion-resistant and high-strength, making them ideal for fluid conveyance, mechanical equipment and food safety piping systems.

Material properties – quality of bent steel pipes

To maintain the integrity of the metal structure, stainless steel is used and formed using a precise cold bending process – perfect for all stainless steel pipe bending requirements.

Precise dimensional parameters for bent steel pipe solutions

General tolerances for bent structures such as siphons: ±0.3-0.5 mm

Bending radius: standard 3D (30 mm); solutions from 1D to 5D are also available

Ovality: ≤5% to ensure optimal sealing of the pipe system

Chemical pipelines: Corrosion-resistant pipeline connections for corrosive media such as acids and alkalis

Automotive oil circuits: High-pressure bending of steel pipes - fuel and brake system components

We offer optional electrolytic polishing or passivation to further improve corrosion resistance – perfect for demanding applications in steel pipe bending.

We provide you with customized processing services for non-standard stainless steel pipes, including material reports and 3D drawing docking services.

Contact us now for technical advice on professional bending of stainless steel pipes or special solutions for bending stainless steel pipes!