Large Wheel Welding Parts | Durable | Precision Welding | Customization

Core Advantages

Stable Structure: The large wheel components are welded from 4.3mm thick, 76*76mm Q345 square tubes (approximately 3"*3"). The sophisticated welding process results in high weld strength, capable of withstanding significant pressure and impact, ensuring stable operation under high-speed rotation and heavy loads. It is also resilient to deformation and breakage, providing reliable assurance for safe equipment operation.

High Concentricity: Advanced positioning and machining processes are employed during the welding process to strictly control the concentricity of the wheel, ensuring minimal error. This ensures smoother wheel rotation, reduces vibration and noise, and improves overall equipment performance and service life.

Flexible Customization: We can customize large wheel assemblies and welded parts in various sizes, specifications, and materials to meet diverse customer needs. Whether it's a different diameter, thickness, or specialized material, we can precisely manufacture them, meeting a wide range of industrial applications.

Technical Details

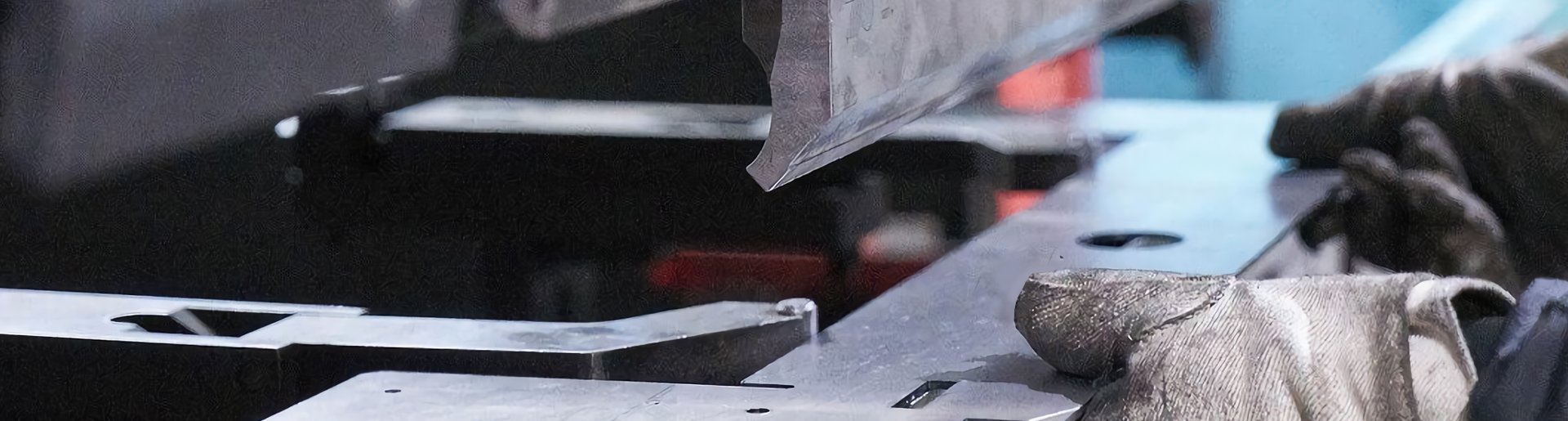

Welding Technology: Advanced welding technology is employed to ensure a stable welding process and high-quality welds. Welding parameters such as current, voltage, and speed are precisely adjusted to ensure sufficient weld penetration and excellent weld formation.

Material Selection: To ensure the wheel's load-bearing capacity and reliability, high-strength and high-toughness steel pipes and metal plates are selected as raw materials.

Why Choose Us

Experience: Since our establishment in 1997, we have accumulated extensive welding experience, particularly in welding large wheel components with mature techniques and processes. We understand the welding properties of various steels and can provide customers with professional solutions.

Professional Team: We have a professional R&D and production team with superb welding skills and extensive practical experience. From product design and raw material procurement to production and processing, every step is strictly controlled to ensure that product quality meets standards.

Modern Equipment: We are equipped with modern welding equipment, CNC cutting machines, and other processing equipment and testing instruments to ensure product processing precision and quality.

Quality Assurance: We have established a comprehensive quality control system and strictly control the quality of every large welded component of the wheel assembly. From visual inspection and non-destructive testing to mechanical performance testing and precision testing, we ensure that our products meet quality standards before shipment. Our company typically utilizes secondary welding when constructing large welded structures. This process combines groove welding with cap welding to ensure 100% penetration on complex joints, such as tube-to-tube fillet welds. This process has been shown to reduce the detection rate of internal defects by 82% compared to single-piece welding.

Analysis of the Advantages and Disadvantages of Secondary Welding

Quality Advantages:

Reduced welding stress and distortion

Reduced crack susceptibility

Improved weld metal microstructure and properties

Process Flexibility:

Allows mid-process review and adjustment

Suitable for complex structures

Easily controlled welding sequences

Economic Aspects:

Reduced requirements for welder one-off operations

Reduced use of expensive tooling

Reduced scrap