Product Overview

This mounting bracket is designed specifically for boat trailers and optimized for 4" (W) x 5" (H) trailer tongues. It offers excellent fit, load-bearing performance, and rust-resistant finish, providing a stable and reliable connection and securing solution for boat trailers.

Adaptability

Optional screw lengths allow for flexible selection based on various installation requirements. Installation tolerances are strictly controlled to ≤ 1mm, ensuring a perfect fit with the boat trailer structure. This greatly improves installation convenience and accuracy, reduces installation time and effort, and ensures a secure installation.

Performance Advantages

Lightweight and High Load-Bearing Capacity

- Weighing only 2.7 kg, it offers a significant weight advantage over similar products, effectively reducing the overall weight of the boat trailer and lowering fuel consumption. - With a static load capacity of up to 120 lbs (approximately 54 kg), the hollow structure reduces weight while maintaining uncompromised strength through rational mechanical design. This bracket can safely and stably carry related equipment and components, providing reliable support for the normal operation of the boat trailer.

Long-Lasting Rust Resistance

The surface is electrostatically powder-coated and available in RAL colors, meeting the individual color requirements of each user while significantly enhancing the bracket's rust resistance. This bracket has passed salt spray testing and exhibits excellent seawater corrosion resistance. Even under harsh, high-salt spray and humid marine environments, it effectively prevents rust and corrosion, extending the product lifespan and reducing maintenance costs.

Material and Craftsmanship

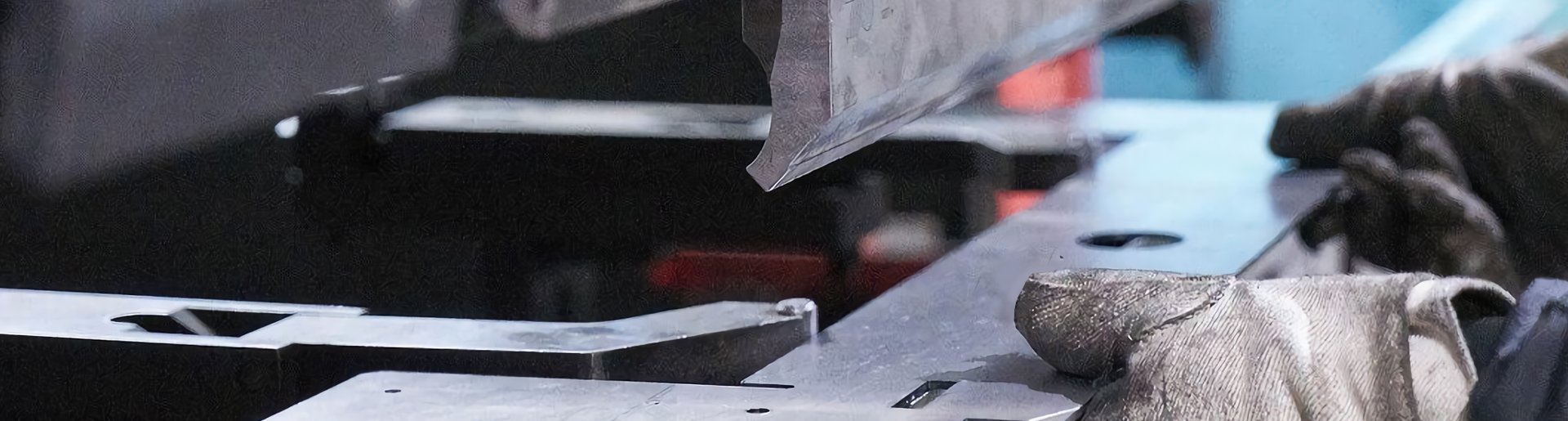

Material

The primary material is Q235B cold-rolled steel, a steel with excellent comprehensive mechanical properties. It offers moderate strength, excellent ductility, and weldability, meeting the requirements of boat trailer mounting brackets. The thickness of the main load-bearing components is 3 mm, ensuring the bracket remains stable and resists deformation and damage even under significant external forces. The laser cutting and welding process is used. Laser cutting ensures high dimensional accuracy and smooth cuts, reducing subsequent processing steps. The mature and reliable welding process securely connects all components, ensuring the stability and reliability of the overall bracket structure.

User Evaluation

-

Nicholas Dierser 1

The Agricultural Forgings produced by Kailai are of good quality.

-

Nicholas Dierser 2

The Agricultural Forgings produced by Kailai are of good quality.