Core Advamtages:

Leading Precision: Utilizing advanced laser cutting technology, cutting accuracy reaches up to ±0.05mm, ensuring precise bracket dimensions and a perfect fit for the equipment, providing a solid foundation for stable operation.

High-Quality Materials: Selected high-strength stainless steel, carbon steel, and other high-quality metal materials offer excellent corrosion and oxidation resistance. They withstand long-term use in harsh environments such as humidity, high temperatures, and strong acids and alkalis, resisting damage and deformation, extending their service life.

Stable Structure: The unique bending design provides enhanced structural stability, capable of withstanding greater pressure and impact, effectively preventing loosening and shifting, ensuring safe and reliable operation of the equipment.

Flexible Customization: We can customize fixed brackets in various shapes, sizes, and specifications to meet diverse customer needs. From simple geometric shapes to complex custom structures, we can precisely create them to meet a wide range of application scenarios.

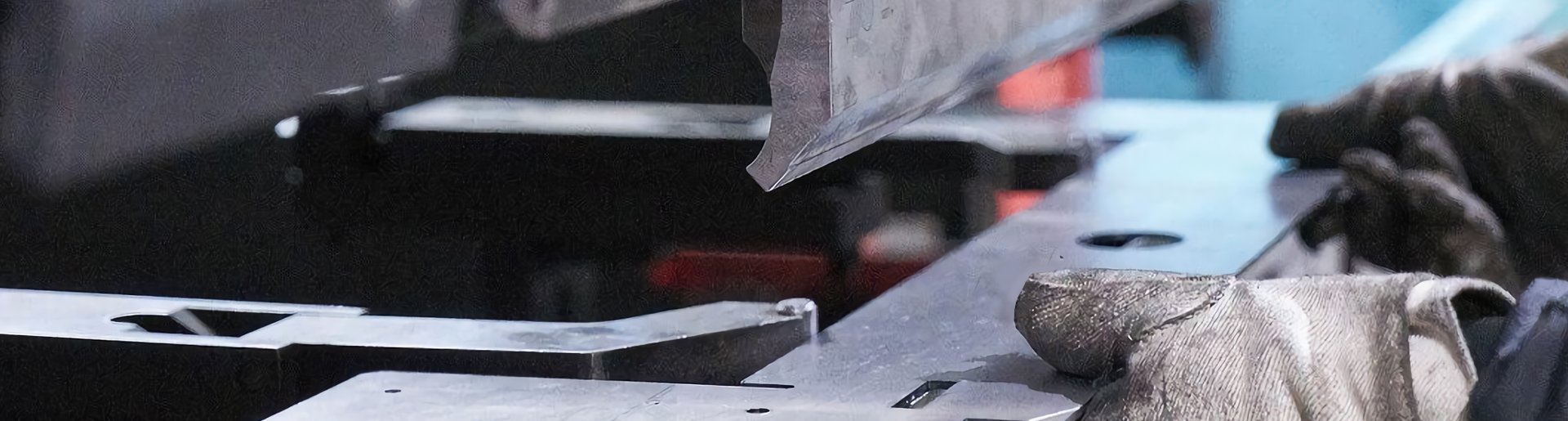

Kaile Factory Laser Cutting Machine

Customized Details

Cutting Process: Laser cutting delivers fast speeds, smooth cuts, and is free of burrs and slag. The heat-affected zone is minimal, minimizing material degradation. Bending Precision: We utilize high-precision CNC bending equipment with precise program control to achieve precise bending, ensuring every bend angle and dimension meets design requirements.

Surface Treatment: We offer a variety of surface treatments, such as galvanizing, plastic spraying, and electrophoresis, to enhance the bracket's corrosion resistance and aesthetics, meeting the individual needs of diverse customers.

Why choose us?

Experience: Since our establishment in 1997, we have specialized in bent brackets for many years, accumulating extensive production experience and expertise. We are familiar with the processing characteristics of various metal materials and are able to provide customers with high-quality solutions.

Modern Equipment: We utilize a comprehensive range of modern equipment, including laser cutting, bending, and welding, to ensure product accuracy and efficiency. We continuously introduce new technologies and equipment to enhance our competitiveness.

Quality Assurance: We have established a strict quality control system. From raw material procurement to finished product delivery, every step undergoes rigorous inspection and control to ensure product quality meets national standards and customer requirements.

Get Advice Now If you are interested in our laser-cut bent brackets or require a customized solution, please contact us today.

Product Other

-

Cross-Shaped Sheet Metal Stamping and Deep Drawing Parts | High Strength, Precision Forming, Quick AdjustmentGet Price Now

Cross-Shaped Sheet Metal Stamping and Deep Drawing Parts | High Strength, Precision Forming, Quick AdjustmentGet Price Now -

Galvanized Metal Cable Tray - 1mm Patterned Galvanized Custom SolutionGet Price Now

Galvanized Metal Cable Tray - 1mm Patterned Galvanized Custom SolutionGet Price Now -

Fixed bracket laser cutting and bending | Precision machining | Stable and durable | CustomizableGet Price Now

Fixed bracket laser cutting and bending | Precision machining | Stable and durable | CustomizableGet Price Now -

Kailai Product custom steel wire rope clamp high strength and quick clampingGet Price Now

Kailai Product custom steel wire rope clamp high strength and quick clampingGet Price Now