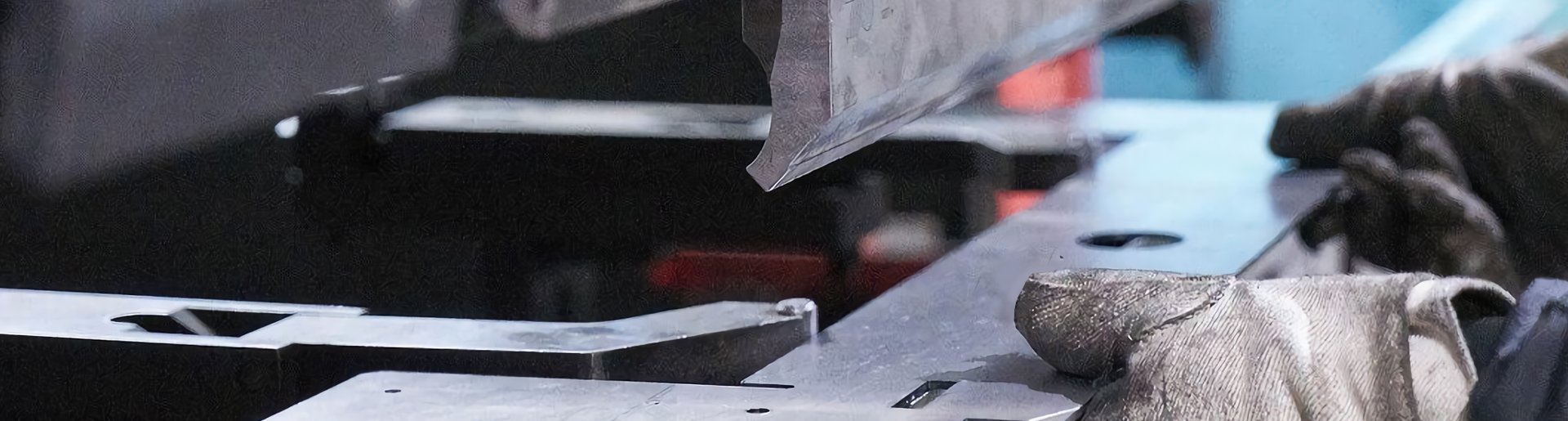

Product Core Parameters and Process Characteristics

Material: This product's base material is 1mm thick 304 stainless steel plate (0Cr18Ni9). Its chemical composition complies with GB/T 3280-2015, containing 18%-20% chromium and 8%-10.5% nickel. It exhibits excellent intergranular corrosion resistance and mechanical strength (tensile strength ≥520 MPa, elongation ≥40%).

Welding: The welding process utilizes fully automatic TIG (tungsten inert gas) welding. The welding current is controlled within the range of 80-120A, with argon shielding gas purity ≥99.99% and a stable flow rate of 15-20 L/min to ensure an oxidation-free weld pool. Post-weld testing is performed using both UT (ultrasonic testing) and MT (magnetic particle testing), achieving a 100% weld pass rate and meeting JB/T 4730.3-2020 Level I requirements.

Surface: This product is untreated, maintaining the original 304 stainless steel surface (Ra ≤ 1.6μm). It can be used in environments with humidity ≤ 90% and has passed a 48-hour salt spray test without rust. Overall dimensional tolerances are controlled to ±0.1mm, and flatness is ≤0.5mm/m, meeting the requirements of precision assembly. Applications

Widely suitable for various industry scenarios:

Kitchenware: Such as stainless steel sinks and stovetop connectors, acid and alkali resistant and easy to clean;

Medical Devices: Suitable for instrument housings and workstation components, meeting hygienic standards;

Precision Instruments: Suitable for sensor mounting and internal equipment support structures, ensuring stability;

Decoration: Suitable for metal art installations, display stands, etc., highlighting an industrial aesthetic;

Industrial Accessories: Suitable for pipe connectors, equipment covers, etc., withstanding complex working

conditions.

Customization Details

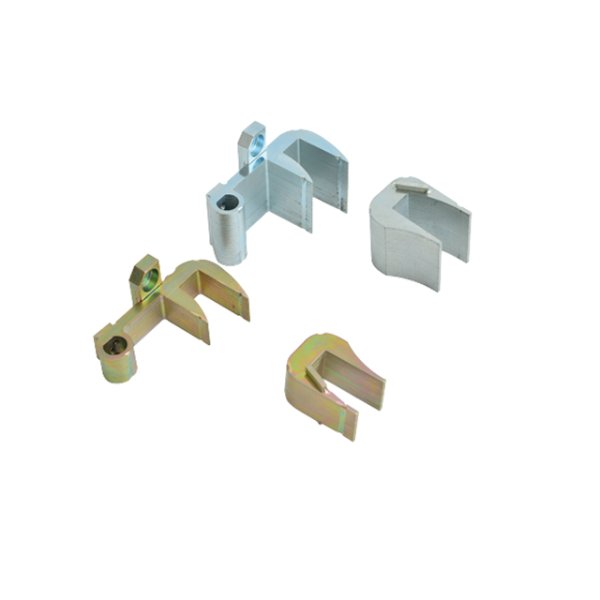

In addition to 304 stainless steel, materials can be replaced with Q235 carbon structural steel (lower cost), DC03 cold-rolled steel plate (excellent formability), and SPCC ordinary cold-rolled steel (versatility).

Surface treatment options include nickel plating (for enhanced wear resistance), spray coating (customizable colors and insulation), galvanizing (for improved rust resistance), and chrome plating (for increased surface hardness).

Dimensional parameters are fully customizable, including length, width, thickness (0.5mm-5mm), and custom shapes. We can precisely replicate customer drawings or samples to meet individual needs.